Changes to ANSI/NEMA MW 01000-2025, Magnet Wire

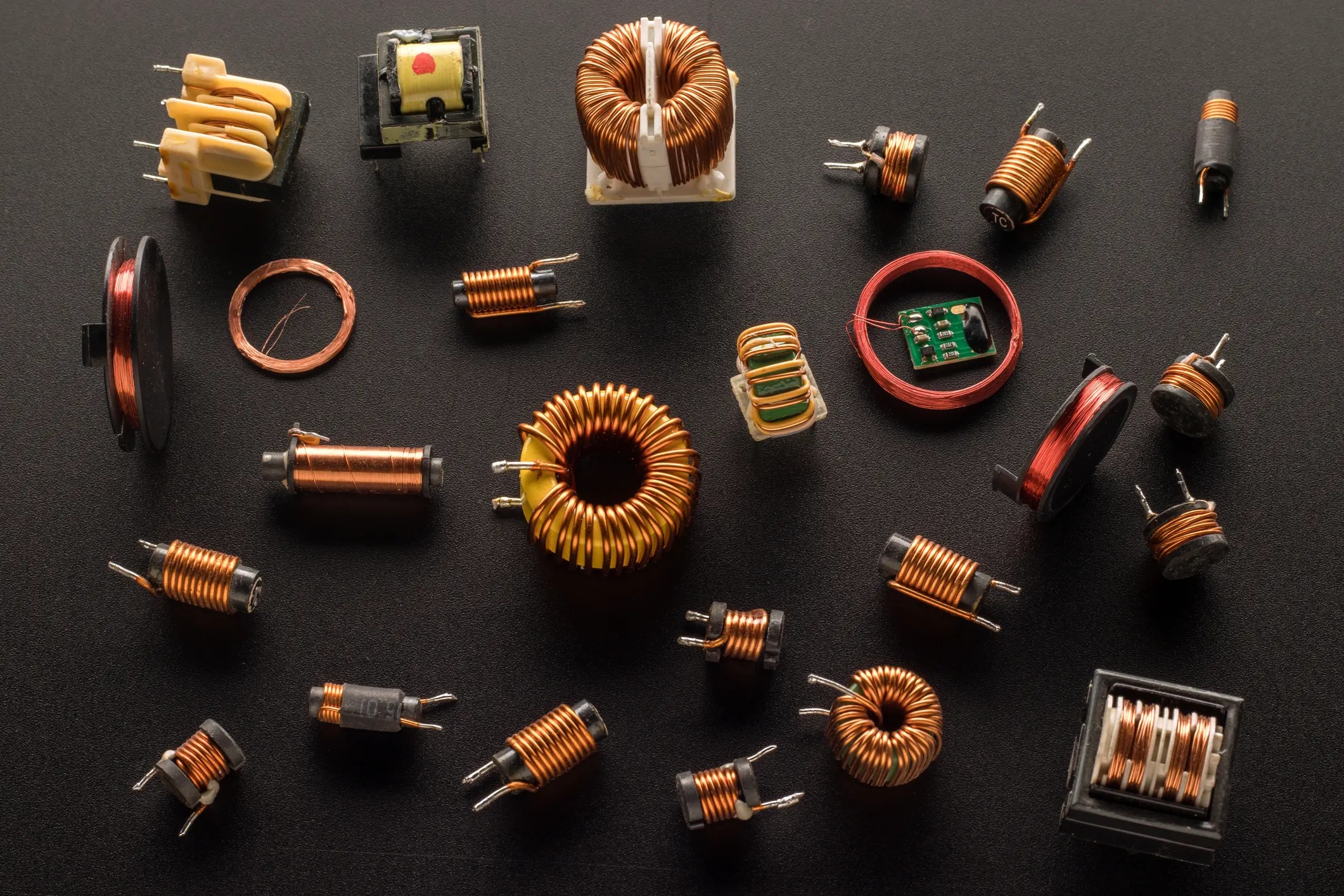

In a precise and convenient form, NEMA MW 01000-2025: Magnet Wire, which revises ANSI/NEMA MW 1000-2023, presents all existing NEMA standards for magnet wire, including those for round, rectangular, and square film-insulated and/or fibrous covered copper and aluminum magnet wire for use in electrical apparatus.

Using the NEMA MW 01000-2025 Document

NEMA MW 01000-2025 includes the definitions, ordering information, material requirements, type designations, dimensions, construction, performance, and test methods for magnet wire generally used in the winding of coils for electrical apparatus. These considerations are essential for manufacturers of magnet wire and products containing the material. Such products include transformers, speakers and headphones, motors, potentiometers, MRI machines, and any other systems that involve an electromagnet.

To use this American National Standard, it is advised in the NEMA MW 01000-2025 document that users first review Part 1 for general information common to all types of magnet wire. Then in Part 2, locate the specification for the type of insulation and conductor of interest. This indicates the requirements that the need to be met for the user and refers to Part 3 for test procedures and corresponding test values.

ANSI/NEMA MW 01000-2025 Revision

Due to the importance of magnet wire as a component of so many products, magnet wire standard is regularly revised, with the NEMA MW 01000-2025 edition superseding the 2023 version. While this new revision doesn’t affect compliance with products manufactured during a time when a previous version of the standard was in effect, it is applicable for the fabrication of all current products containing magnet wire.

Below are the major highlights of changes made to NEMA MW 01000-2025, the current version of the magnet wire American National Standard:

- Numerous sections were revised to assign tolerances to Heat Shock oven conditioning temperatures according to ASTM D5423

- New Section 123-C, “Polyamideimide with Self-Bonding Overcoat Film Insulated Round Copper Magnet Wire Thermal Class 180/Bond Performance at 180°C, was added

- New Section 124-C, “Polyimide with Self-Bonding Overcoat Film-Insulated Round Copper Magnet Wire Thermal Class 180/Bond Performance at 180°C,” was added

- Section 136-C, “Polyurethane Overcoated with Polyamide and Self-Bonding Overcoat Film-Insulated Round Copper Magnet Wire for Solderable Applications Thermal Class 155,” was revised to correct the Thermal Class 130 requirement to 155

- Specifications on the optical micrometer used for measuring dimensions of ilm-insulated magnet wire were added to Section 3.2.1, “Round Wire”

- The description of where Heat Shock test failures shall be disregarded was clarified in Section 3.3.1, “Elongation and Mandrel Wrap Method”

- The description of the principle of the Deflection Method for Springback was updated in Section 3.7.2.1, “Principle of Test”

- Section 3.8.1, “Test Procedure—General,” was revised to recommend, rather than require, wearing gloves during Dielectric Breakdown testing

- Section 3.8.3, “Twisted Pair Method,” was revised to better clarify how to determine compliance with Dielectric Breakdown requirements using the Twisted Pair Method

- Section 3.8.4, “Wound Pair Method,” was revised to better clarify how to determine compliance with Dielectric Breakdown requirements using the Wound Pair Method

- Section 3.8.5, “Bend Method,” was revised to better clarify how to determine compliance with Dielectric Breakdown requirements using the Bend Method

- Section 3.8.6, “Cylinder Method,” was revised to better clarify the Cylinder Method procedure for Dielectric Breakdown testing

- Section 3.8.7, “Shot Box Electrode Method (Alternative to 3.8.2 Foil Electrode Method)” was revised to clarify that the rectangular wire tested to the Shot Box method for determining compliance with Dielectric Breakdown requirements is to be U-bent flatwise

- The use of conductive brush electrodes in High Voltage Continuity testing was specified in 3.9.1.2, “Equipment”

- Section 3.9.1.3 was deleted, thereby removing notes placed more than 20 years ago on the use of dual sheave electrodes

- Section 3.51.1.2, “Needle Scrape (10-30 AWG),” was revised to clarify how to determine that bare conductor exposure has occurred

- Section 3.52, “Dielectric Breakdown at Rated Temperature,” was revised to clarify which Dielectric Breakdown at Rated Temperature procedures apply to round wire up to 8 AWG, and to round wire larger than 8 AWG

- Section 3.54.3, “Short-Term (24-Hour) Exposure Test—(Screening),” was revised to specify that sealed tubes are to cool for a minimum of two hours

- Section 3.57.2.2.3, “Solvent Bonding,” was revised to indicate the specific clause numbers for bond strength test procedures

- Section H.7.2, “Equipment,” was revised to specify an across-the-board fault-detection circuit fault current of 18 mA

- Table H-7, “In-Line High-Voltage Continuity Test Voltages Dimensions in mm,” was deleted due to the revised fault current in H.7.2

- Table H-8, “Loads Applied to the Crossing Point,” was updated (and renumbered H-7) with revised inline HVC test voltages

NEMA MW 01000-2025: Magnet Wire is available on the ANSI Webstore.

Questions About ANSI/NEMA MW 01000?

This American National Standard was developed and published by the National Electrical Manufacturers Association (NEMA).

Please direct any technical questions relating to this American National Standard to the developer. You can find the contact information for all standard developing organizations (SDOs) here: Who to Contact for Standards Related Questions.