SAE J 1273-2021: Hydraulic Hose Assemblies Recommended Practices

As it offers linear and rotary motion with high force and torque with a smaller, lighter package than other forms of power transmission, numerous industries depend on fluid power.

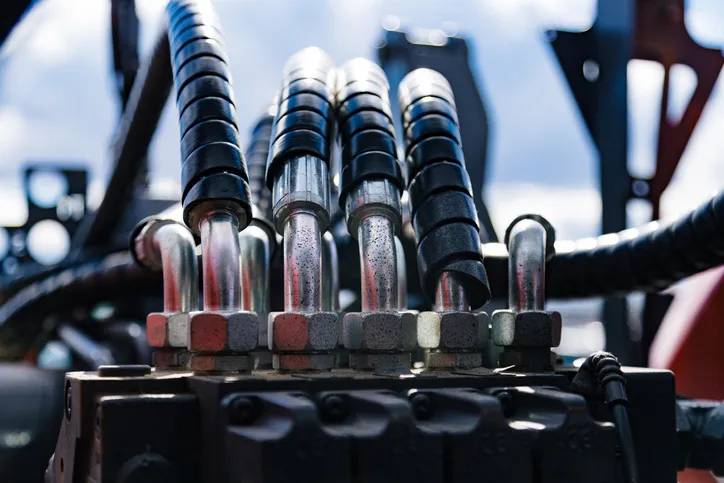

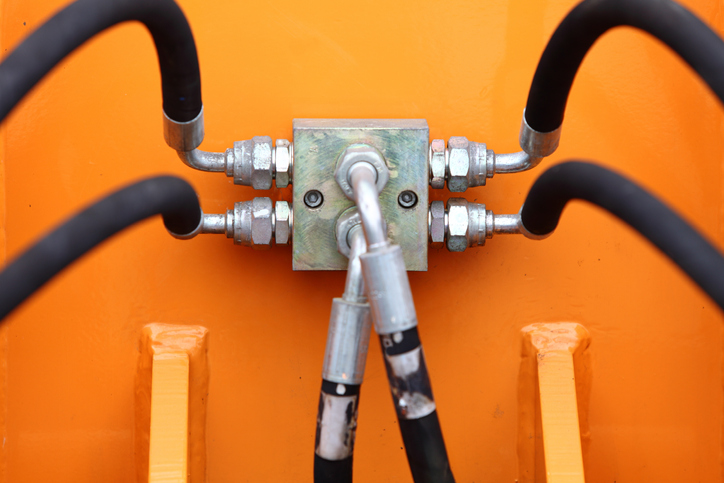

If the fluid—whether liquid (typically oil) or gas (typically compressed air)—is the lifeblood of the operation, the hose assemblies are the veins. As materials and systems that transmit energy via pressurized hydraulic fluids or compressed air while in contact with hundreds of thousands of workers every day, hydraulic hose assemblies need to remain safe and reliable. SAE J 1273-2021: Recommended Practices For Hydraulic Hose Assemblies assures this.

Dangers of Hydraulics and Hydraulic Hose Assemblies

According to the Occupational Safety and Health Administration (OSHA), several hydraulics-related injuries and fatalities occur each year. Hydraulics is found typically in off-highway equipment and heavy machinery, so these are the main accident areas.

With systems that can operate over 2,000 psi, hydraulic hose systems undergo immense levels of fluid pressure. According to SAE J 1273-2021, excessive pressure is a factor that can accelerate assembly failure. For this reason, hose selection is based on system pressure, along with several related factors, such as suction, external pressure, and permeation.

A myriad of other variables lead to hose and fitting degradation—temperature, electricity, abrasion, paint, ultraviolet light, and saltwater. If a hose stops functioning properly, the results can be quite dangerous.

For example, if a pressurized hose system blows apart, the fittings can be thrown off at high speed and the loose hose can flail at extreme force. SAE J 1273-2021 refers to this as “whipping hose.” In April 2018, one of these events, occurring while an employee was adjusting the wire length setting on an evaporative air cooler, resulted in a broken ankle.

Fluid injections are another notable hydraulics-related hazard. These events, which take place when fine streams of escaping pressurized fluid penetrate the skin and enter the human body, can lead to severe tissue damage and loss of limb. In September 2017, one such event took place after an employee was replacing a hydraulic valve on a reach stacker. While loosening the hydraulic line, the line blew off and forced hydraulic fluid into the base of his thumb.

In addition to these hazards, conveyed fluids can present dangers associated with burns, fire, and explosions. The fluid passing through the hose can also generate static electricity, which makes static-electric discharge and resulting fires and explosions an area of concern.

SAE J 1273-2021: Recommended Practices For Hydraulic Hose Assemblies

Improper selection, fabrication, installation, or maintenance of fluid power hose assemblies can result in serious injury or property damage. To help address the hazards associated with hydraulic hose systems, SAE J 1273-2021 outlines numerous safety considerations during all phases of design and use. Therefore, the recommended practices outlined in this document can reduce the risk of injury or damage.

For example, in the event of a fluid injection, SAE J 1273-2021 advises to see a doctor immediately and not to delay or treat as a simple cut, along with further key considerations.

Ultimately, SAE J 1273-2021 addresses the selection, routing, fabrication, installation, replacement, maintenance, and storage of hose and hose assemblies for hydraulic fluid-power systems. As noted in the scope, many of these recommended practices also may be suitable for other hoses and systems.

Who Can Use SAE J 1273-2021?

Since fluid power systems are complex and need extensive knowledge of hose systems, all-inclusive, step-by-step instructions are not practical and fall beyond the scope of SAE J 1273-2021. Instead, this document is intended to be a guide for users, who may fall in various skill levels.

For those new to hose use in fluid-power systems, SAE J 1273-2021 outlines practices to note during each phase of design and use. For more-experienced designers, these considerations can help achieve proper results. Less experienced users who need more information can consult specialists such as suppliers and manufacturers.

Changes to SAE J 1273-2021

SAE J 1273-2021 revises the 2019 edition of the same SAE International recommended practice. In this revision, verbiage was added to Section 6.6, “Reuse of Hose and Fittings,” to eliminate the option of repairing hose assemblies in the field.

SAE J 1273-2021: Recommended Practices For Hydraulic Hose Assemblies is available on the ANSI Webstore.

Referenced Documents in SAE J 1273

The following SAE and ISO standards are referenced in the SAE J 1273-2021 document and can aid compliance and safety efforts to those who work with hydraulic hose assemblies:

SAE J343: Test And Test Procedures For SAE 100R Series Hydraulic Hose And Hose Assemblies

SAE J514: Hydraulic Tube Fittings

ISO 3457 – Earth-Moving Machinery – Guards – Definitions And Requirements