IPC 2152, Current Carrying Capacity in Printed Board Design

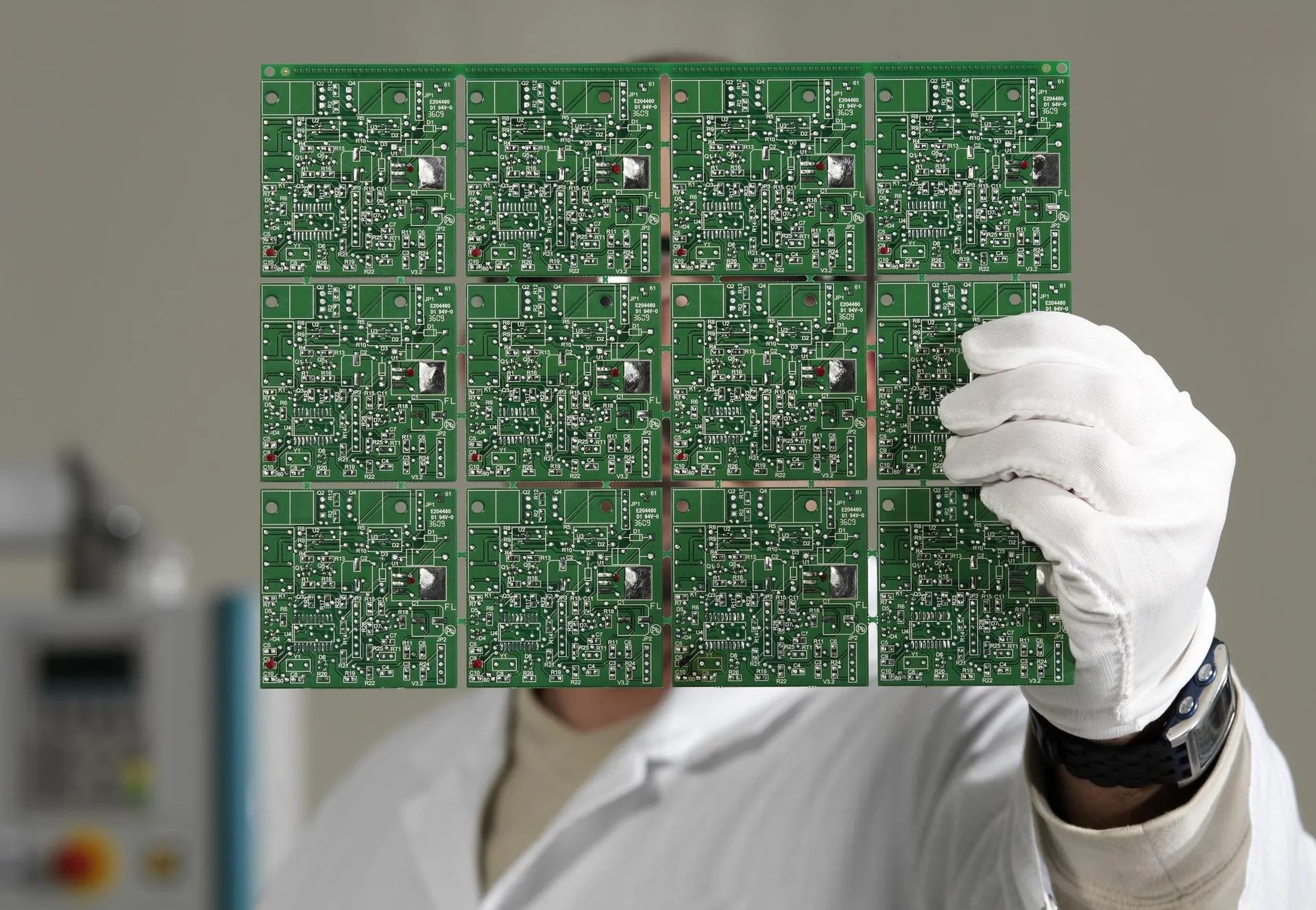

Determining the current-carrying capacity of printed circuit boards (PCBs) is critical for reliable and safe operation. This process assures that traces can handle the required current without overheating, which could lead to component damage, fire hazards, and signal integrity issues. IPC-2152, Standard for Determining Current Carrying Capacity in Printed Board Design is a guide that can be used in the design and evaluation of copper conductors in printed boards.

Determining the Current Carrying Capacity of a PCB

The current-carrying capacity of conductors on a printed circuit board (PCB), also known as trace current capacity, refers to the maximum amount of electrical current a trace can safely carry without causing excessive heating or damage. This capacity is crucial in determining the reliability and performance of electronic devices.

The current-carrying capacity of a PCB trace is determined by several factors, including trace width, thickness (copper weight), temperature rise, and the surrounding environment. IPC 2152 is the industry standard for determining the current capacity, temperature rise, and width of a trace in a printed circuit board.

What Is IPC 2152?

IPC 2152 outlines how to determine the current-carrying capacity of conductors on printed circuit boards. This document is the sole industry standard for determining appropriate internal and external conductor sizes on printed boards as a function of the current carrying capacity required and the acceptable conductor temperature rise.

The standard provides guidance on how thermal conductivity, vias, copper planes, power dissipation, printed board material, and thickness all factor into the relationship between current, conductor size, and temperature. The purpose of IPC 2152 is to provide guidance on determining the appropriate conductor sizes on the finished printed boards as a function of the current carrying capacity required and the acceptable conductor temperature rise.

What Factors Influence the Current-Carrying Capacity?

Factors that influence current-carrying capacity of a trace on a printed circuit board (PCB) include:

- Trace width: Wider traces can carry more current due to their increased cross-sectional area.

- Copper thickness: Thicker copper traces can carry more current.

- Allowable temperature rise: Higher allowable temperature rises (within safe limits) allow for higher current ratings (but may impact board reliability).

- Layer position: Traces on outer layers can dissipate heat more effectively than inner layers, potentially allowing for higher current capacities.

- Ambient conditions: Surrounding temperature and airflow affect heat dissipation and thus current capacity.

- PCB material and structure: Different materials have different thermal conductivities, affecting heat dissipation.

Understanding and accurately determining current-carrying capacity is essential for designing reliable and safe electronic devices. IPC 2152 exists to lay out the requirements for determining the appropriate internal and external conductor sizes on printed boards.

IPC-2152, Standard for Determining Current Carrying Capacity in Printed Board Design is available on the ANSI Webstore.