ANSI/ESD S13.1-2019: Electrical Soldering/Desoldering Tools

Soldering or desoldering sensitive modern components like microprocessors, memory chips, and sensors requires strict adherence to electrostatic discharge (ESD) safety protocols to prevent permanent damage. ANSI/ESD S13.1-2019: Electrical Soldering/Desoldering Hand Tools provides a standardized way to test whether soldering and desoldering tools are safe for use around such sensitive electronics.

What Is Soldering and Desoldering?

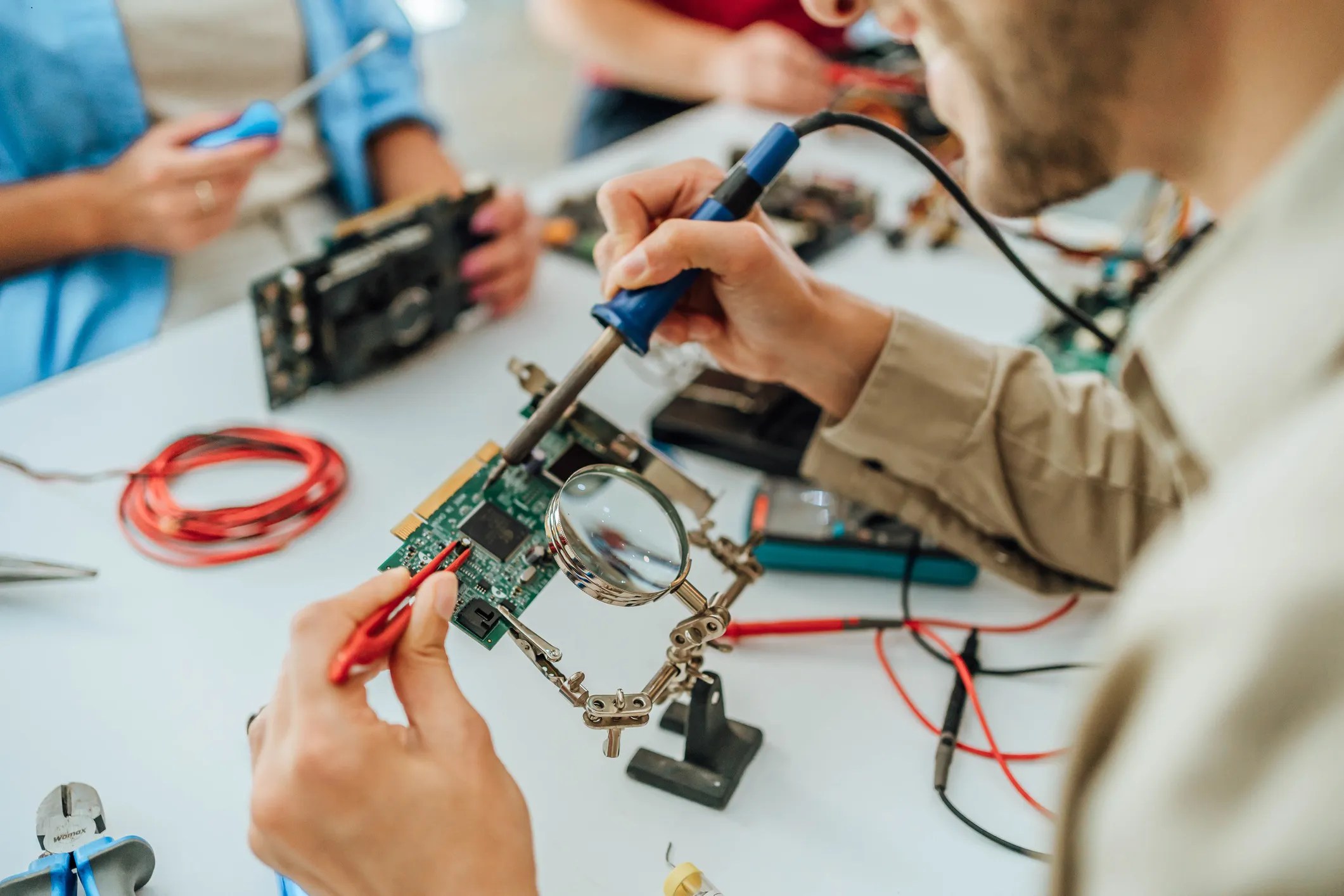

Soldering is the process of creating a strong, permanent bond between electronic components by melting a metal alloy called solder with a hot iron to join them, while desoldering is the opposite process of removing that solder to disconnect or replace components. Soldering is used to assemble circuits, and desoldering is used for repairs, modifications, or salvaging parts.

Soldering and desoldering are high-risk processes for electrostatic discharge (ESD)—which can be a major cause of component failure in the electronics industry.

Why Is ESD Protection Crucial for Soldering and Desoldering?

ESD occurs when static electricity discharges from one object to another, potentially causing severe damage to sensitive electronics. ESD protection is crucial for soldering and desoldering electronics because a sudden static discharge can cause permanent, sometimes invisible, damage to sensitive electronic components. This can lead to premature failure and reliability issues. Without ESD protection, components can suffer from internal damage like metal melts, junction breakdowns, or oxide failures, resulting in both immediate malfunctions and latent defects that cause problems later.

By following the guidelines set out in ANSI/ESD S13.1-2019, you can minimize these ESD risks during these critical steps, helping to assure electronic assemblies stay intact and fully functional.

What Is ANSI/ESD S13.1-2019?

ANSI/ESD S13.1-2019 provides electrical soldering/desoldering hand tool test methods for measuring current leakage, tip to ground reference point resistance, and tip voltage. This American National Standard is used during the procurement, qualification, and verification of soldering/desoldering hand tools.

Assuring Electrical Integrity: Procedures in ANSI/ESD S13.1-2019 for Soldering and Desoldering Tools

ANSI/ESD S13.1-2019 details test methods to assure the electrical integrity of soldering and desoldering hand tools used in ESD sensitive work areas. It specifies procedures for measuring the tool’s current leakage, resistance between the tip and a ground reference point, and tip voltage to prevent damage to electronic components from electrical overstress (EOS) or ESD. The procedures are applicable for tools used in ESD-safe work areas or on ESD-sensitive materials.

Importance of Adhering to ANSI/ESD S13.1-2019

Complying to ANSI/ESD S13.1-2019 for soldering and desoldering tools is essential for anyone working with sensitive electronics like computers, servers, and smartphones. By choosing ESD-safe tools, maintaining proper grounding, and adhering to best practices for ESD control, you can assure the safety and reliability of projects and products.

Where to Find ANSI/ESD S13.1-2019

ANSI/ESD S13.1-2019: Electrical Soldering/Desoldering Hand Tools is available on the ANSI Webstore.

ANSI/ESD S13.1-2019 is developed by the Electrostatic Discharge Association (ESDA).

Please direct any technical questions relating to this American National Standard to the developer. You can find the contact information for all ANSI-accredited standards developers here: List of ANSI-Accredited Standards Developers (ASDs).

For further information, please refer to: Who to Contact for Standards Related Questions.

You can learn more about the importance of ESD control in our YouTube Video about ANSI/ESD S20.20-2021.