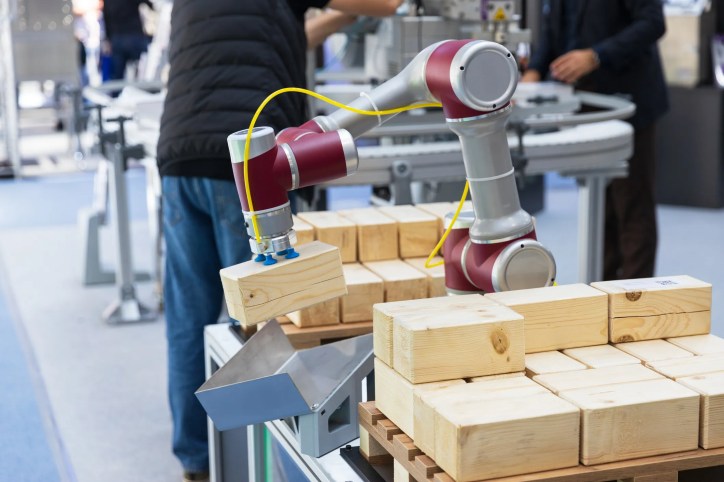

More than 4.2 million industrial robots have been deployed worldwide as of 2023, with the number of new installations continuing to grow globally across various industries— including the automotive industry, aerospace, supply chain logistics, and additive manufacturing. By automating repetitive, dangerous, and precise tasks like welding, assembly, and material handling, industrial robots are critical in boosting productivity, safety, and quality in manufacturing. ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3): Industrial Robots and Robot Systems – Safety Requirements (Parts 1, 2, and 3) provides updated guidelines for anyone building, integrating, or operating robots in industrial settings, assuring personnel safety through updated best practices.

What Is ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3)?

ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3) is the updated American National Standard for industrial robot safety. It provides the latest safety guidelines for industrial robots, covering industrial robots (Part 1), industrial robot applications and robot cells (Part 2), and use of industrial robot cells (Part 3), incorporating updates from international ISO standards (ISO 10218) with explicit functional safety, risk assessment, personnel safety, new rules for end-effectors, and cybersecurity considerations, replacing the 2012 version.

Understanding the Three Parts of the R15.06 Standard

ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3) consists of three parts. These new R15.06 Parts 1 and 2 feature extensive updates that focus on making functional safety requirements more explicit rather than implied. This shift enhances clarity and usability, making compliance more straightforward for manufacturers and integrators alike. Part 3 addresses the user.

Part 1: Safety Requirements for Industrial Robots

This part covers the safety guidelines for the robot itself, including requirements for its manufacture, remanufacture, and rebuilding. This includes features like safety functions, new classifications for robots, testing methodologies, and addressing collaborative robot applications.

Part 2: Safety Requirements for Industrial Robot Applications and Robot Cells

This part addresses the integration and installation of the robot and its applications into a workplace or “robot cell.” It specifies how to safeguard personnel who work with the robotic systems and includes new guidance for end-effectors and manual loading procedures.

Part 3: Safety Requirements for Users of Industrial Robot Cells

This part focuses specifically on safety requirements for the users of industrial robot cells. It covers the safe operation, risk assessment, and personnel safety within robotic work environments.

History of the ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3) Standard

ISO 10218‑1, the international standard that forms the basis for ANSI/A3 R15.06, was originally published in 2006. It lays out essential safety requirements for robot manufacturers, focusing on design-stage precautions to minimize risks before a system is even installed in the workplace.

Five years later, in 2011, ISO 10218‑2 was introduced. This companion standard shifts focus to system integration, outlining how industrial robots should be safely implemented in real-world environments. It addresses key issues such as installation, operation, maintenance, and decommissioning of robot systems—especially within robot cells and complex applications. To create a unified approach for U.S. stakeholders, the Robotic Industries Association (RIA) combined both ISO standards into ANSI/RIA R15.06‑2012, published the following year.

In 2021, the Association for Advancing Automation (A3) absorbed its robotics, advanced vision, and motion control sub-associations—meaning RIA merged with a few other organizations to become A3. The organizations encompassing A3 include:

- The Robotic Industries Association (RIA): Founded in 1974, the RIA served the North American robotics industry. It focused on advancing the use of robotics through education, safety standards, and promoting integrated solutions.

- Advancing Vision + Imaging Association (AIA): Formed in 1984, the AIA was the world’s largest machine vision trade group. It supported the industry through standards development, market research, and educational events.

- The Motion Control & Motor Association (MCMA): The MCMA was a trade group dedicated to promoting motion control and motor technologies. MCMA was formed in 2015 from a merger of the Motion Control Association (MCA), founded in 2006, and the Small Motors & Motion Association (SMMA), founded in 1975.

This consolidation across organizations aimed to streamline standards development, foster cross-disciplinary collaboration, and better represent the converging nature of modern automation technologies. By merging, A3 now offers members and the broader automation industry a single resource for a wider range of technologies and applications.

Furthermore, in 2025—over a decade since the release of ANSI/RIA R15.06‑2012—the Association for Advancing Automation (A3) published ANSI/A3 R15.06-2025: the newly revised American National Standard for industrial robot safety covering robots and robot systems. ANSI/A3 R15.06-2025 updates and replaces ANSI/RIA R15.06‑2012, harmonizing with ISO 10218‑1:2025 and ISO 10218‑2:2025.

ISO 10218‑1:2025 was expanded from 50 to 95 pages, with ISO 10218‑2:2025 growing from 72 to 223 pages, and ANSI/A3 R15.06-2025 grew from 162 to 374 pages. Such updates are considered necessary for keeping pace with changes to the industry and the technologies that help them to function.

Published on October 29, 2025, ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3) is a comprehensive 403-page document that includes all three parts of the R15.06 standard.

What’s New in the 2025 Update to ANSI/A3 R15.06 (Parts 1 +2) & Why It’s Significant

ANSI/A3 R15.06-2025 (Part 1 + 2) represents the most significant safety revision in U.S. robotics in over a decade. Revising ANSI/RIA R15.06-2012, it is a landmark update robot safety in the U.S., bringing clarity of safety requirements, new considerations like cybersecurity, and refined terminology. Here are some key updates in this version of the standard:

- Enhanced safety clarity – Functional safety requirements are now made explicit instead of implied. This helps manufacturers and integrators better understand what compliance demands.

- Collaborative applications – Rather than treating “collaborative robot” as a robot type, the new standard focuses on the application, allowing for more nuanced safety controls in human-robot interaction environments. This terminology update reflects a maturation in how experts think about safe human-robot interaction (i.e., the robot is only one component in a larger, collaborative interaction).

- New Terminology – “Monitored standstill” replaces “safety-rated monitored stop;” “collaborative application” replaces “collaborative robot;” and “safeguarded space” now includes dynamic protections like sensors and scanners, not just physical barriers.

- Cybersecurity as safety – The 2025 standard brings cybersecurity into the safety planning fold. Robots and robot systems now have to consider cyber threats as part of overall safety risk.

- Manual load/unload and end‑effectors – Areas that previously had more limited (or separate) guidance are now incorporated into the standard. This helps clarify responsibilities and steps for safe operation, not just design.

- Updated tests & classifications – New categories for robots, updated test methods, better classification of safety functions to keep pace with robotics tech evolution.

In sum, ANSI/A3 R15.06-2025 (Parts 1+2) delivers clearer guidance, smarter classifications, and a roadmap for safety in the era of intelligent automation. The standard empowers manufacturers and integrators to design and deploy safer systems more confidently while supporting innovation without compromising human well-being.

What Does “Collaborative Technologies and Applications” Mean?

Collaborative technologies and applications refer to a general term for any tool that facilitates teamwork, communication, and efficiency for people. There is a focus on how the robot is used and hence its collaborative application. Collaborative technologies and applications can be either synchronous (real-time) or asynchronous (time-delayed) and include, for example:

- Hand-guiding controls that allow an operator to physically lead the robot’s motions

- Speed and separation monitoring (SSM) that use sensors to keep a safe distance or slow the robot when humans approach

- Power and force limiting (PFL) that utilize built-in limits, so the robot can safely bump into a person without causing serious harm

From a safety perspective, a process is deemed collaborative after assuring every aspect of the whole human-robot interaction is safe by design. This includes risk assessments, safety functions, and protective measures around the robot and its workpiece or tool.

Who Uses ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3)?

ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3) is intended for a wide range of professionals involved in the lifecycle of industrial robot systems—from design and integration to daily use and maintenance. The standard serves as a critical guide to ensuring safety, performance, and compliance across industrial environments where robots are deployed.

- Robot manufacturers use the standard to design machines that meet essential safety and performance requirements.

- System integrators rely heavily on the standard when planning and building robot work cells.

- End users and facility operators (including manufacturers and plant managers) turn to the standard to safely install, operate, and oversee robot systems in real-world applications. ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3) also guides them through safe procedures for maintenance and decommissioning.

- Health and safety professionals use the standard as a benchmark for evaluating workplace risks and as guidance to establish robust safety policies, training protocols, and compliance programs that protect employees.

- Maintenance and technical staff also play a vital role, using the standard to guide inspections, repairs, troubleshooting, and upgrades.

- Regulator and auditors use the standard as a reference point during compliance inspections and audits, and ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3) provides an objective framework for evaluating whether a robotic system meets the required safety criteria.

- Educators and trainers in robotics, automation, or occupational safety rely on the standard to teach students and professionals about current best practices in robotic system design and safe operation.

Where to Find ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3)

The release of ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3) marks a major milestone in robot safety. Whether you are a manufacturer, integrator, or plant operator, aligning with this American National Standard assures safer workplaces, easier global trade, and future-proof operations. Stay ahead by understanding the changes now and preparing your teams and systems for what is next.

ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3) is developed by the Association for Advancing Automation (A3).

Please direct any technical questions relating to this American National Standard to the developer. You can find the contact information for all standard developing organizations (SDOs) here: Who to Contact for Standards Related Questions.

ANSI/A3 R15.06-2025 (Parts 1+2) / ANSI/A3 R15.06-3-2025 (Part 3): Industrial Robots and Robot Systems – Safety Requirements (Parts 1, 2, and 3) is available on the ANSI Webstore and in the following Standards Packages:

- ANSI B11.19 / ANSI/RIA R15.06 – Industrial Robots Safety Set

- ANSI/RIA R15.06 / ANSI B11.0 / ANSI B11.19 – Industrial Robots and Machinery Safety Package

- ANSI/RIA R15.06 / RIA TR R15.306 – Industrial Robots Safety Set

- ANSI/RIA R15.06 / RIA TR R15.306 / RIA TR R15.406 – Industrial Robots Safety Package

- ANSI/RIA R15.06 / RIA TR R15.306 / RIA TR R15.406 / RIA TR R15.606 – Industrial Robots Safety Package

- ANSI/RIA R15.06 / RIA TR R15.306 / RIA TR R15.606 / RIA TR R15.806 – Industrial Robots Safety Package

- ANSI/RIA R15.06 / RIA TR R15.406 – Industrial Robots Safety Set

- ANSI/RIA R15.06 and ISO 13849 – Safety of Machinery and Industrial Robots Package

- ANSI/RIA R15.08-1 / ANSI/ITSDF B56.5 / ANSI/RIA R15.06 – Industrial Mobile Robots Package

- ANSI/RIA R15.08-1 / ANSI/RIA R15.06 / ANSI/ITSDF B56.5 / ISO 3691-4 – Industrial Mobile Robots Package

- RIA 360 Robot Super Safety Bundle