AAMI TIR17:2024—Sterilization of Health Care Products

Medical professionals are legally obligated to provide patients with a standard of care, which includes proper sterilization of medical equipment. This helps to assure that all microorganisms, including bacteria, viruses, and spores, are completely eliminated from the medical devices and instruments used on patients—thereby safeguarding patient health. AAMI TIR17:2024—Compatibility of materials subject to sterilization details guidance for the sterilization of healthcare materials.

What Is AAMI TIR17?

AAMI TIR17:2024 provides guidance for health care product manufacturers in the qualification of polymeric materials, ceramics, and metals for use in health care products that are sterilized by the following modalities:

- Radiation (gamma, electron beam, or X-ray)

- Ethylene oxide

- Moist heat (steam)

- Dry heat

- VH2O2

- Nitrogen dioxide

- Peracetic acid vapor

- Liquid peracetic acid

- Hydrogen peroxide–ozone

- Chlorine dioxide.

These modalities are individually addressed in Section 3 and Annexes C through K of AAMI TIR17:2024. Furthermore, annexes in this technical information report (TIR) address the specific sterilization modality concerns.

Guidance on the processing of materials is carried over from AAMI TIR17:2017 and is provided in Section 5. General guidance on the testing of materials is provided in Section 6. Accelerated aging program information is provided in Section 8. If it has been carried over from AAMI TIR17:2017, or if it has been subsequently published elsewhere, AAMI TIR17:2024 provides references.

This TIR was developed to provide additional guidance in order to improve quality and reduce the costs and time required for performing material qualifications.

A TIR is not subject to the same formal approval process as a standard; however, a TIR is approved for distribution by a technical committee and the AAMI Standards Board.

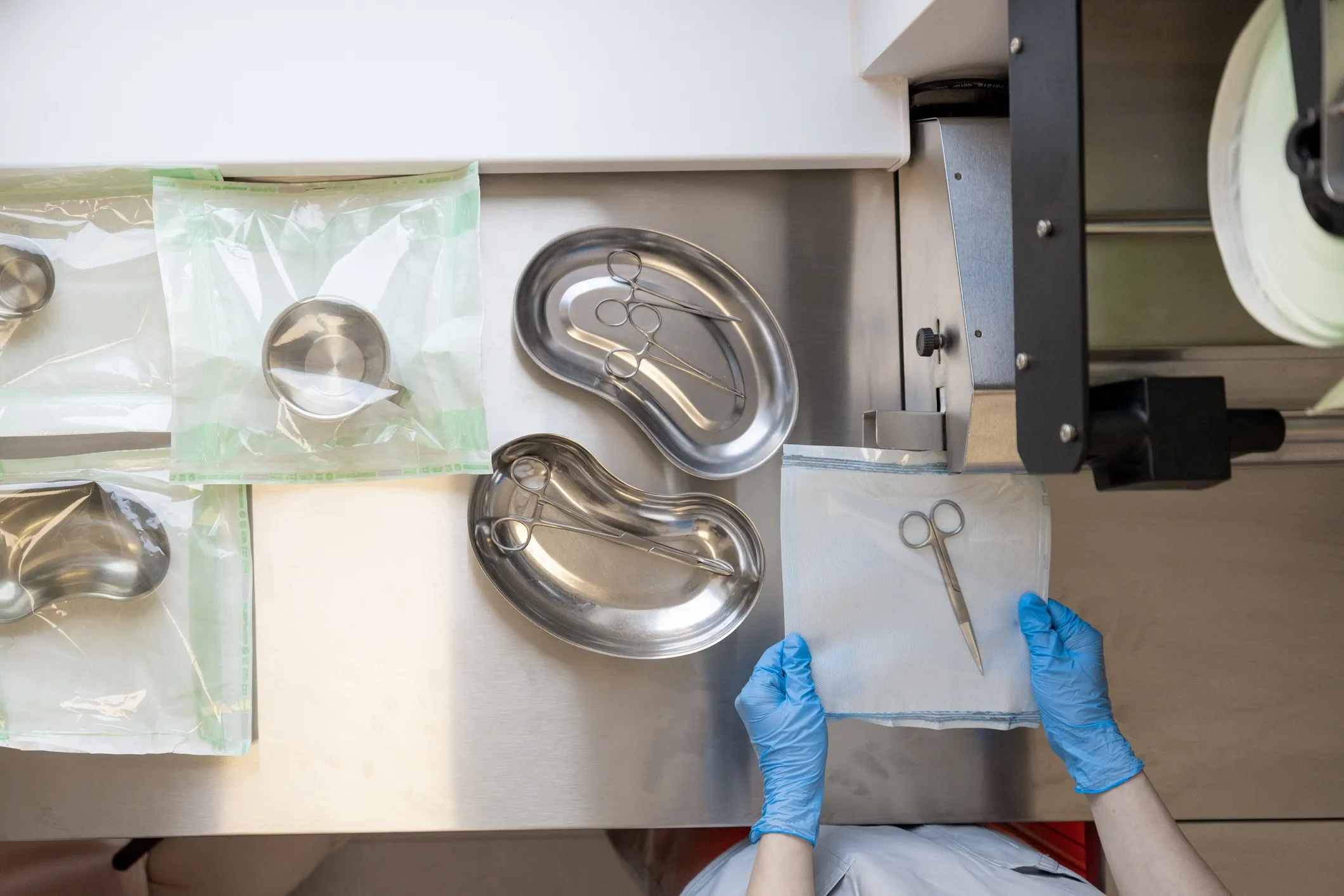

Sterilization of Medical Materials

Sterilization of medical materials is paramount in preventing the transmission of infectious diseases. The three common features in medical instrument sterilization processes are air removal, a steam injection and sterilization phase, and steam removal and drying. In the design and development of medical products requiring sterilization, AAMI TIR17:2024 specifies that consideration should be given to customer needs, finished device performance requirements, materials, and sterilization methods. Ultimately, it is crucial that sterile devices meet their intended performance requirements and are safe and effective.

Revisions in the 2024 Edition of AAMI TIR17

AAMI TIR17:2024 supersedes AAMI TIR17:2017. The 2024 edition of this TIR includes additional information on chlorine dioxide sterilization, refined information on aging programs as they relate to material compatibility and expanded information on addressing material compatibility concerns when changing sterilization processes or modalities.

What Are the Benefits of Sterilizing Medical Equipment?

There has been a move toward sterilization due to an increased focus on the risks of transferring infection between patients when reusing medical instruments. In invasive procedures like surgery, sterilization of medical equipment is especially important because there is a higher risk of introducing pathogenic microbes, potentially resulting in infection. Besides preventing the transmission of infections, other benefits from sterilizing medical equipment include the following:

- Protecting equipment

- Decreasing bio-burden and the pathogenic load

- Preventing corrosion of tools

- Preventing disease transmission

- Removing breeding grounds for the surviving germs

- Helping assure the safe use of non-invasive and invasive medical devices

AAMI TIR17:2024—Compatibility of materials subject to sterilization is available on the ANSI Webstore and in the Standards Package: AAMI TIR28 / AAMI TIR16 / AAMI TIR17 – Ethylene Oxide Sterilization Package.