ANSI B11.6-2022: Manual Turning Machines (Lathes) Safety

The “mother of all machine tools” is also known as the lathe, the first machine tool which led to the invention of other machine-based tools during the Industrial Revolution. Lathes evolved into hydraulic lathe machines, and later they incorporated electric motors, replacing line shafting. In the mid-20th century, the Computer Numerical Control (CNC) lathe machine was introduced, enabling machine tools to be operated via computerized numerical control. From then, manual and CNC lathes have existed in the manufacturing industries, and ANSI B11.6-2022: Safety Requirements For Manual Turning Machines [Lathes] With Or Without Automatic Control provides safety requirement for manual lathes.

What is ANSI B11.6-2022?

ANSI B11.6-2022 specifies safety requirements for the design, construction, operation and maintenance of manually controlled horizontal and vertical spindle turning machines, often called lathes. These machines are intended to work metals and other man–made materials, and they utilize manually initiated steps to produce a part by rotating the workpiece against a stationary tool(s) such that the cutting force is from the workpiece and not the tool. This American National Standard largely applies to machine suppliers, modifiers, users, and personnel who have responsibilities for defining and achieving acceptable risk.

What Is a Lathe?

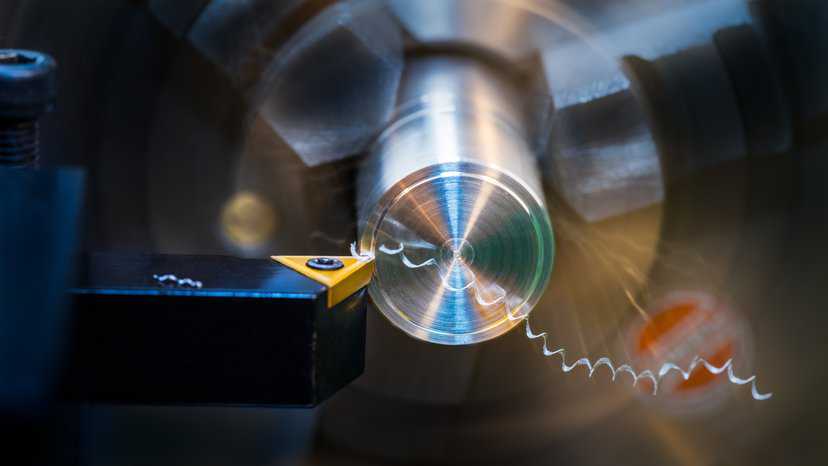

A lathe is a machine that rotates a workpiece, cutting and removing unwanted parts to produce the desired shape with the suitable symmetry and measurable axis of the object. The materials that can be cut with a lathe include steel, aluminum, copper, zinc, wood, and plastic. The movements of a traditional lathe machine are manually controlled by an operator, who adheres to the safety requirements specified in ANSI B11.6-2022. A lathe is capable of performing numerous machine operations and processes, such as turning, cutting, sanding, knurling, boring, undercutting, drilling, deformation, and facing.

What Are Common Lathe Processes?

- Turning: A material removal process when the fixed cutting tool is primarily parallel (or linear) to the rotating workpiece. It is used to make cylindrical parts.

- Facing: A material removal process when the tool is located at the right angle of the turret, removing material from the end of a workpiece to produce a flat surface.

- Parting: A turning operation that uses a single‑point cutoff tool to sever a section of workpiece from raw stock.

- Grooving: A turning operation that works similarly to parting but the workpiece is not severed and instead it creates a narrow cut (a groove) in the workpiece.

- Boring: A cutting process that involves the use of a single-point cutting tool or boring head to enlarge an existing hole in a workpiece.

What Is A Lathe Used For?

Examples of objects that can be produced on a lathe include:

- Screws

- Candlesticks

- Gun barrels, pins

- Cue sticks

- Table legs

- Bowls

- Baseball bats

- Pens

- Musical instruments (especially woodwind instruments)

- Crankshafts.

ANSI B11.6-2022: Safety Requirements For Manual Turning Machines [Lathes] With Or Without Automatic Control is available on the ANSI Webstore. All ANSI B11 standards are available together as the ANSI B11. Machine Tools Safety Package that address the safety requirements for various machine tools like hydraulic power presses, mechanical power presses, power press brakes, shears, manual milling/drilling, grinding machines, and metal sawing.