The first electrical systems to use insulators were telegraph lines, such as the one strung between Washington, D.C, and Baltimore, Maryland in 1844. Now, insulators are used in all electrical devices from tiny cables to giant generators. Insulating electrical cables and wires offers multiple benefits, including enhanced safety, protection against short circuits and environmental factors, improved performance, and compliance with electrical codes. IEC 60085 Ed. 4.0 b:2007— Electrical Insulation – Thermal Evaluation And Designation covers electrical insulation.

What Is Electrical Insulation?

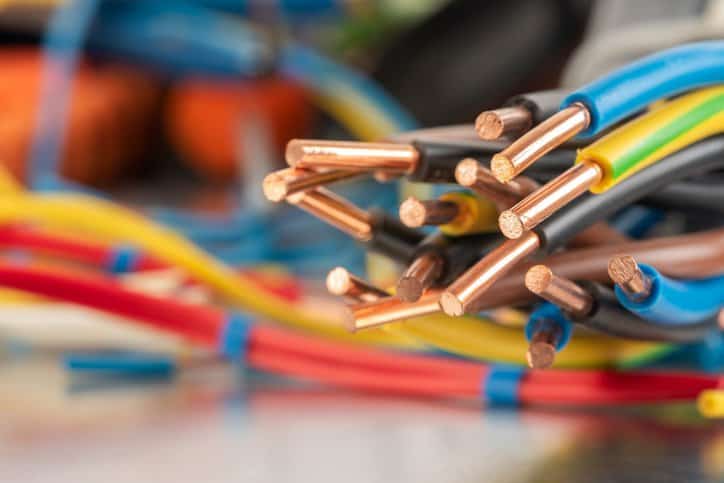

Insulation is the term used for a variety of materials used to reduce the transfer of energy. Insulators have low conduction and thus are used around electric wires to protect the wire from the environment. For effective insulation, it is necessary a nonconductive material, or a material resistant to the flow of electric current. There are three primary categories of wire insulation: plastic (polyvinyl chloride, polyethylene, polypropylene, nylon etc.), fluoropolymers (fluorinated ethylene propylene, thermoplastic elastomers, etc.), and rubber (neoprene, silicone, fiberglass, etc.).

These materials are quite often used to coat electrical wires to prevent the electrical current from traveling outside of the allocated area. Insulation materials resist electrical leakage, prevent the wire’s current from coming into contact with other conductors, and preserves the material integrity of the wire by protecting against environmental threats, such as water and heat. The safety and effectiveness of the wire depend on its insulation.

What Is IEC 60085 Ed. 4.0 b:2007?

IEC 60085 Ed. 4.0 distinguishes between thermal classes for electrical insulation systems and electrical insulating materials. It establishes the criteria for evaluating the thermal endurance of either electrical insulating materials (EIM) or electrical insulation systems (EIS).

- Electrical insulating material (EIM): solid or fluid with negligibly low electric conductivity, or a simple combination of such materials, used to separate conducting parts at different electrical potential in electrotechnical devices

- Electrical insulation system (EIS): insulating structure containing one or more EIM together with associated conducting parts employed in an electrotechnical device

The standard also establishes the procedure for assigning thermal classes. IEC 60085 Ed. 4.0 is applicable where the thermal factor is the dominant aging factor.

History of Electric Insulation Materials

In the early days, insulators were made of ceramic and glass materials. Here is a timeline of the mass-produced insulation materials:

- 1810: Un-vulcanized Rubber

- 1816: Glass Tubes

- 1841: Gutta Percha (a form of natural latex)

- 1844: Vulcanized Rubber – Goodyear Patent

- 1879: Paraffined Jute & Vulcanized Bitumen

- 1880: Natural Rubber

- 1884: Paper Cable (vegetable fiber)

- 1885: Oil Impregnated Paper

- 1933: PVC First used in cable insulation

- 1942: Polyethylene (PE) Developed

- 1970: Polytetrafluoroethylene (PTFE) Cables

In the late 1970s and early 1980s, polymer insulators were used primarily as special designs for extreme applications at a premium cost to the utilities. Polymeric insulators have many advantages over ceramic and glass insulators, including good performance in contaminated environments and being lightweight, vandal resistant, easy to handle, and maintenance free.

Why Is It Necessary to Insulate Wires and Cables?

Insulators help reduce the risk of electrical fires by keeping the electricity in the designated area. In addition, cable and wire insulation prevents the wire’s current from coming into contact with other conductors. The insulation preserves the wire material against environmental threats (e.g., heat or moisture) and resists electrical leakage.

IEC 60085 Ed. 4.0 b:2007— Electrical Insulation – Thermal Evaluation And Designation is available on the ANSI Webstore.