A radiation sterilization validation is used to determine the appropriate sterilization dose for a product, helping establish the pertinent sterilization parameters for health care reprocessing instructions. AAMI CR513:2024— Guidance On Radiation Validation And Routine Maintenance For Single-Use Systems Used For Pharmaceutical And Biopharmaceutical Manufacturing establishes specifications for radiation sterilization validation and routine control.

Sterilization Microbiology

Sterilization is the process of eliminating all forms of microbial life (both vegetative and spore form), including bacteria, viruses, and fungi, from a surface, object, or fluid. This process can be achieved using physical or chemical agents. It is different from disinfection, decontamination, or sanitization, which only reduce the number of microorganisms to a safe level. Sterilization removed all forms of microorganisms. It is important in microbiological laboratories to prepare culture media, reagents, and equipment for sterile conditions.

What Is AAMI CR513?

AAMI CR513:2024 provides guidance on simplified approaches for validation and routine control of single-use systems used for pharmaceutical and biopharmaceutical manufacturing sterilized by radiation. This consensus report provides alternative, scientifically valid approaches that simplify and improve validation and routine control of sterilization for these products.

Radiation Sterilization Validation

If a sterile label claim is required and the sterilization method will be radiation, a validation is required to determine the appropriate sterilization dose. Radiation sterilization validation is a test that determines the appropriate radiation dose to sterilize a product requiring a sterile label claim. It incorporates bioburden testing, a bioburden recovery efficiency test, a sublethal radiation dose (verification dose), a test of sterility, and method suitability (bacteriostasis/fungistasis) testing:

- Bioburden Test: determines the number of viable microorganisms in or on a medical device, container, or component

- Verification Dose Application: uses the bioburden results to determine the proper verification dose from a standard table

- Sterility test: tests the sterility of the irradiated product

- Method Suitability (also known as Bacteriostasis and Fungistasis): confirms the absence of antimicrobial properties present on pharmaceutical products and medical devices

What Are the Single-Use Technologies in Pharmaceutical Manufacture?

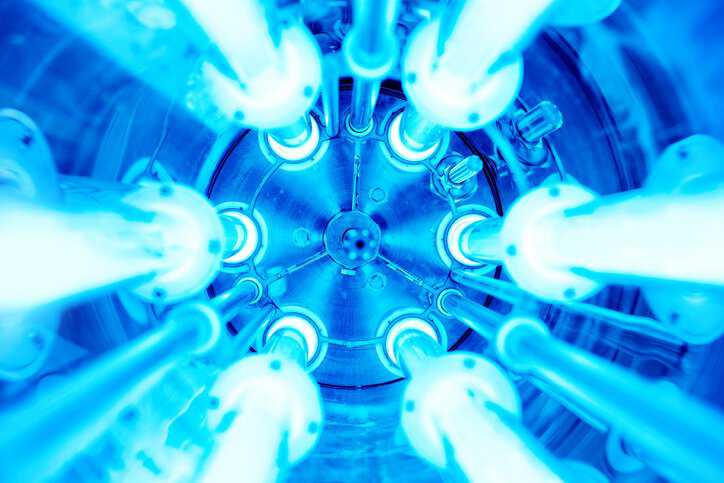

Single-use technologies (SUTs) have been in use since the early 1990. They are products (often made from plastic materials like polypropylene, polycarbonate, polyethylene, and polyvinyl chloride) or solutions used in pharmaceutical manufacturing that are intended to be used once and then thrown away. SUTs include tubing, capsule filters, ion exchange membrane chromatography devices, mixers, bioreactors, product holding sterile bags in place of stainless steel vessels (sterile fluid containment bags), connection devices and sampling receptacles. They are manufactured in a cleanroom, double bagged, and sterilized using gamma, ethylene oxide (EtO), or x-ray sterilization methods.

Why Are Single-Use Technologies Popular?

Single use technologies (SUTs) are increasingly being used and gaining popularity in the pharmaceutical and biotech industry because they offer numerous advantages over traditional stainless steel systems. For example, SUTs are cost effective, efficient, and sustainable as illustrated in the following statistics:

- 40% lower investment costs

- 46% decline in total water and energy consumption

- 35% more favorable CO2 footprint

SUTs reduce cost for both small-scale and large-scale production because they save time, require less instrumentation and utility demand, have lower investment costs, and promote both energy and water savings. Furthermore, SUTs significantly streamline manufacturing operations, reducing turnaround times by replacing the need for extensive cleaning and validation and sterilization processes associated with reusable systems.

AAMI CR513:2024— Guidance On Radiation Validation And Routine Maintenance For Single-Use Systems Used For Pharmaceutical And Biopharmaceutical Manufacturing is available on the ANSI Webstore.